| Previous article | Show list | Next article |

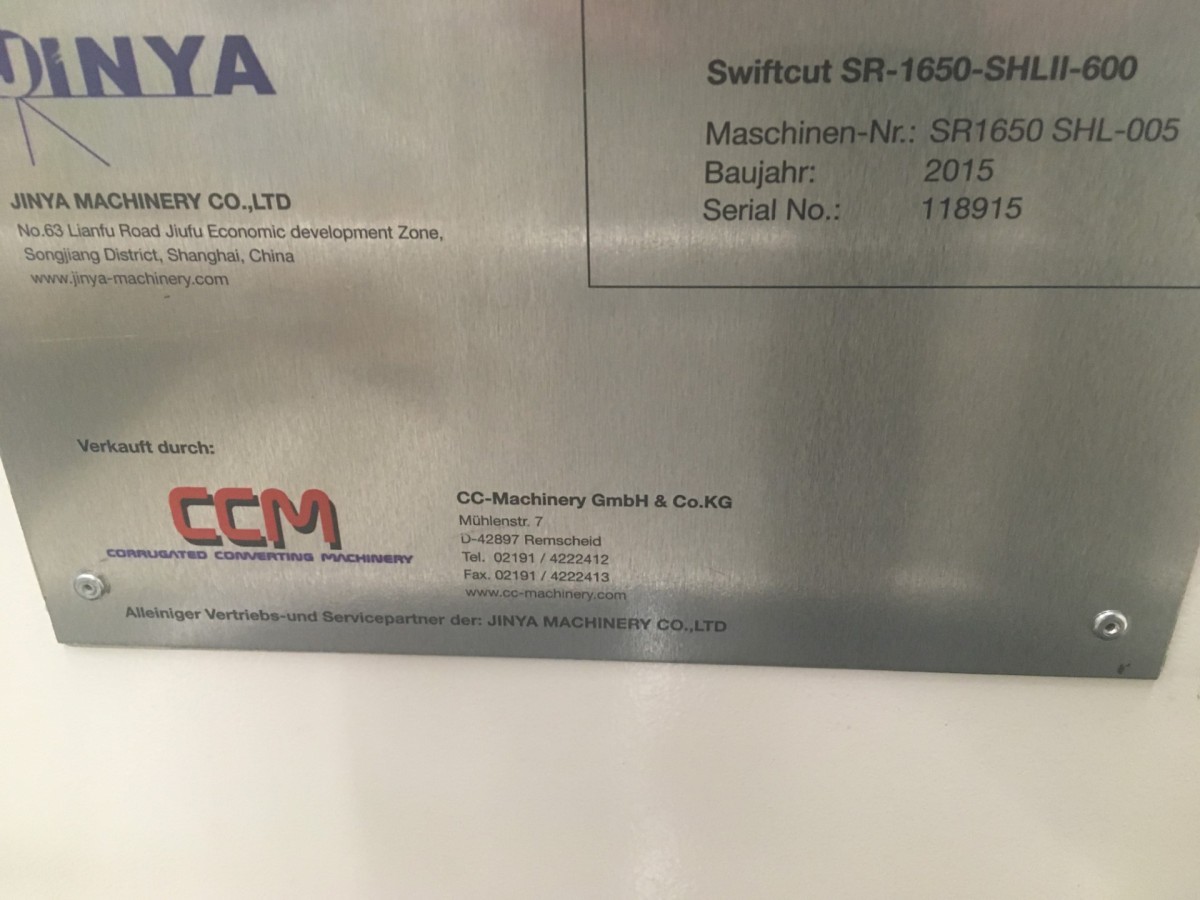

Diecutter Jinya SR1650-SHLII 600

€199.000,00

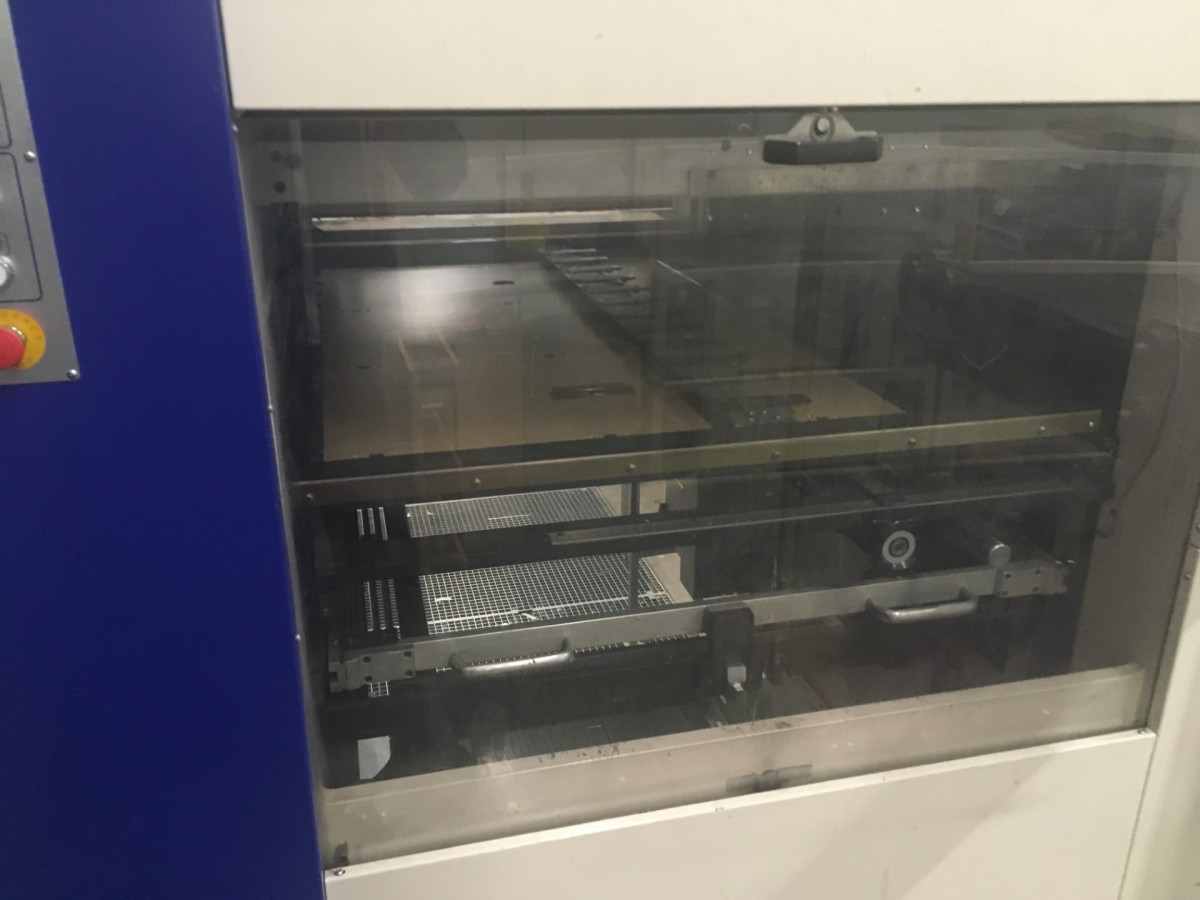

Automatic Diecutter Jinya SR 1650, for die-cutting corrugated board. located in Germany.

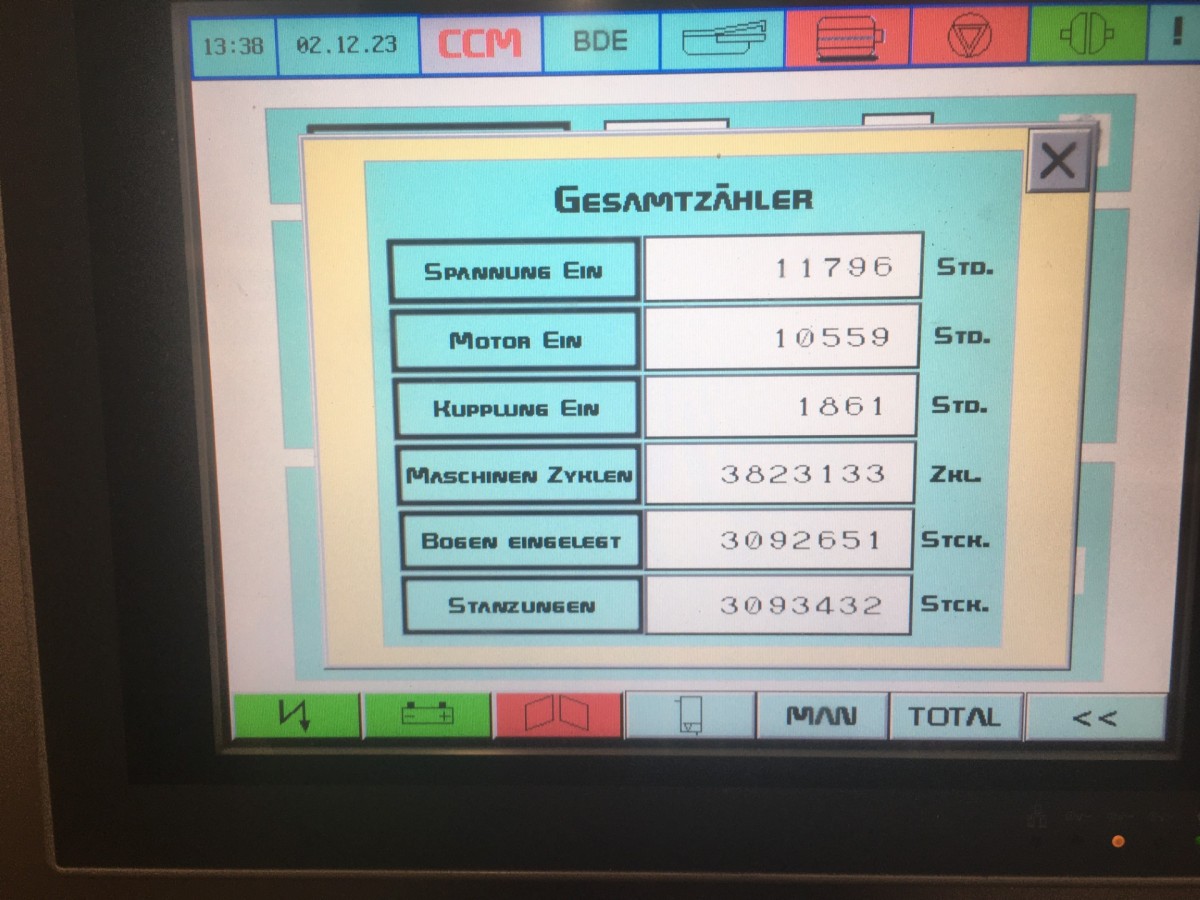

ONLY 3.1 million stroke!

Furnishing:

- Standard sheet insertion for corrugated cardboard formats up to 9 mm thick

- Extended sheet insertion with single sheet alignment Sheet goods

- Stripping station with additional lower frame for stripping pins

- Stacking station for forming high stacks up to 1700 mm high

Generally

High-quality transport chains from Germany

High quality grippers and gripper bars with 0-register alignment system

PLC controlled automatic chain lubrication

Pneumatic chain tensioners with pressure regulation and oil pressure shock absorbers on freewheel wheels

Torque limitation of the chain drive by overload clutch

Mechanical drive via a closed 3-fold cam system

Maintenance-free mechanical connections for secondary functions

Electrical and mechanical standard components from well-known manufacturers

Large touch-screen display for operation and error display

Centerline II fastening system

Single sheet insertion

Transport and alignment section between roll insert and flatbed die cutter

Individual sheet transport from the roll feeder into the punching machine

Sheet transport at the bottom via transport belts and at the top via transport, brush and volcanic pressure rollers

Upper rollers adjustable laterally as well as forwards and backwards

Manually raise and lower the top roll frame for easy removal of format sheets

Single sheet alignment front and side

Independently adjustable page aligners to align each individual format sheet

Punching section

Punching area made of thick-walled cast steel

Mechanical drive of the crucible rocker via pneumatic clutch/brake

Large-sized toggle lever system with stable drive shaft

Closed high-pressure lubrication system with automatic pressure monitoring

Oil cooling unit for optimal lubrication at high speeds

Xb90de2e

Large crucible opening for safe passage of the gripper bars

Air support system under counter punch plate for easy handling

Mechanical locking and pneumatic unlocking of the punching frame

Stripping station

Stable double breakout system

Upper and lower mounting frame for stripping tools

Maintenance-free drive for mechanical breakout movements

Lightweight, stable frame construction designed for high speeds

Easier and quicker installation and removal of stripping tools

For easy access, the upper knockout frame can be moved in height by motor

Lower additional stripping system with frame and stripping pins available

Removal of the gripper edge waste from the side of the machine via the conveyor belt

Technical specification

Article number 41051

Condition

(4) Running condition, good

(4) Running condition, goodIn production

Yes

Availability

Shortly

built in

2015